Working with Trak-TFRC, a hardware development startup focussed on conservation, and researchers in Peru, we developed a low-cost Open-Source Hardware system for collecting wildlife data, for the purposes of conservation.

Current Scenario

For decades the primary means of tracking animals involved the use of VHF transmitters in the form of a collar, tag, backpack or implant.

In order to ascertain the location of an animal, a team of researchers has to go out into the jungle to use a receiver and antenna.

I worked with Trak-TFRC to develop tools with which researchers can automate the process of tracking animals. This enables them to gather increased volumes of data about their behaviour, which directly aids in conservation and research efforts.

We’ve also identified opportunities to develop additional devices that would aid in adjacent tasks, such as collecting images & samples, monitoring traps, and taking measurements.

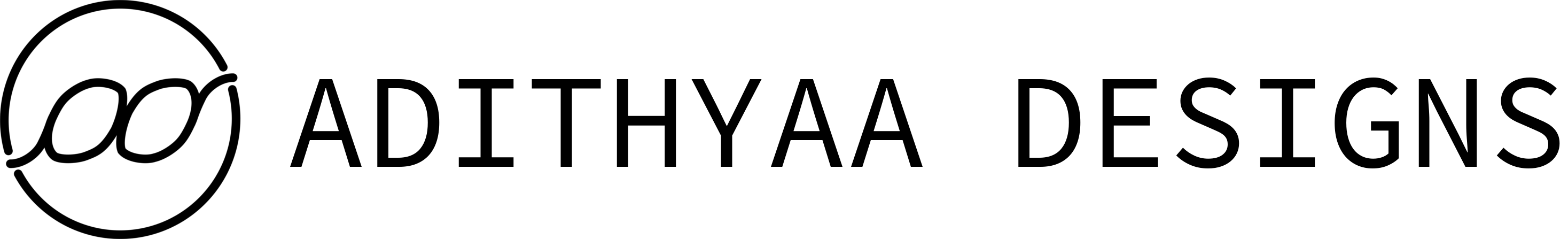

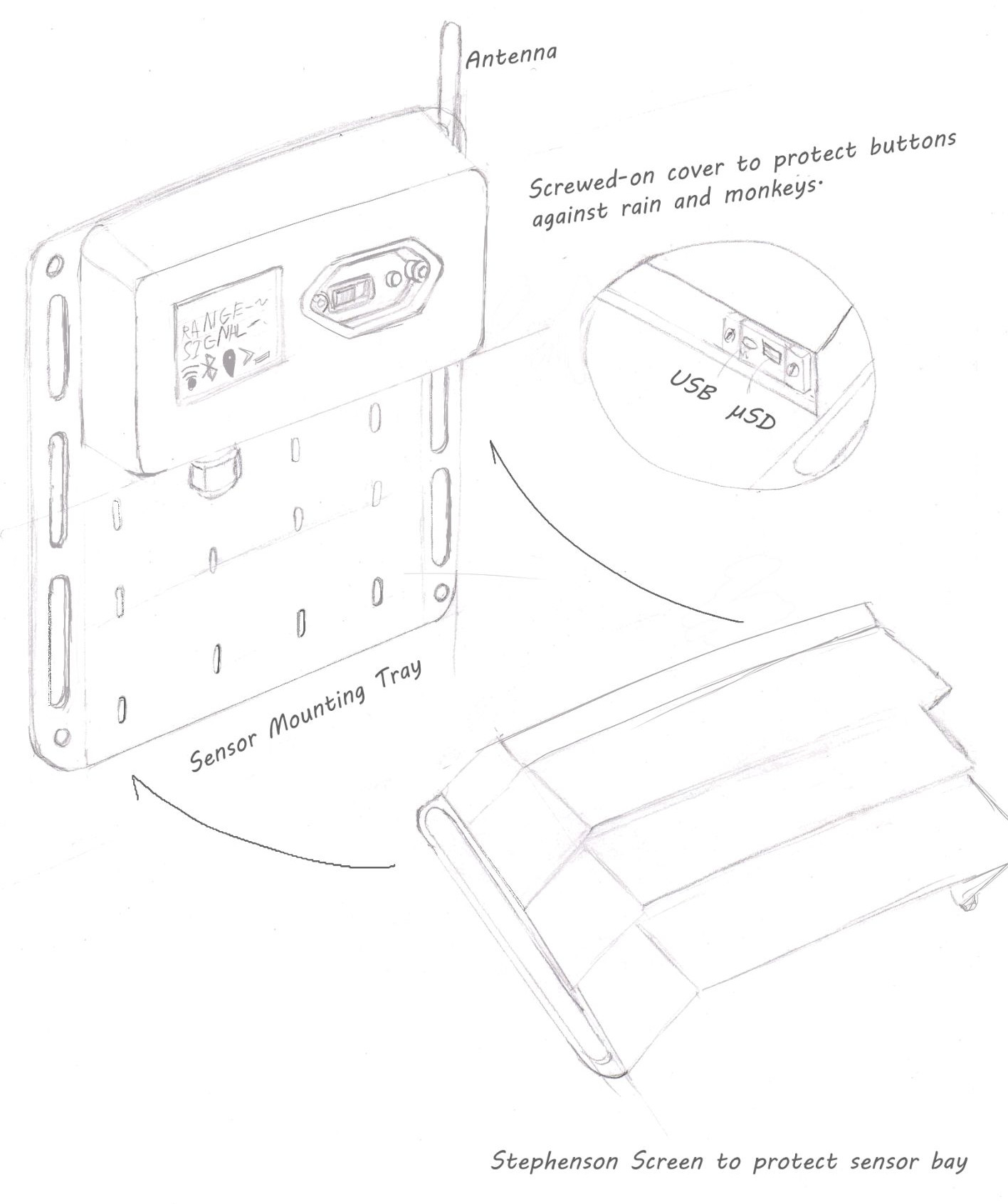

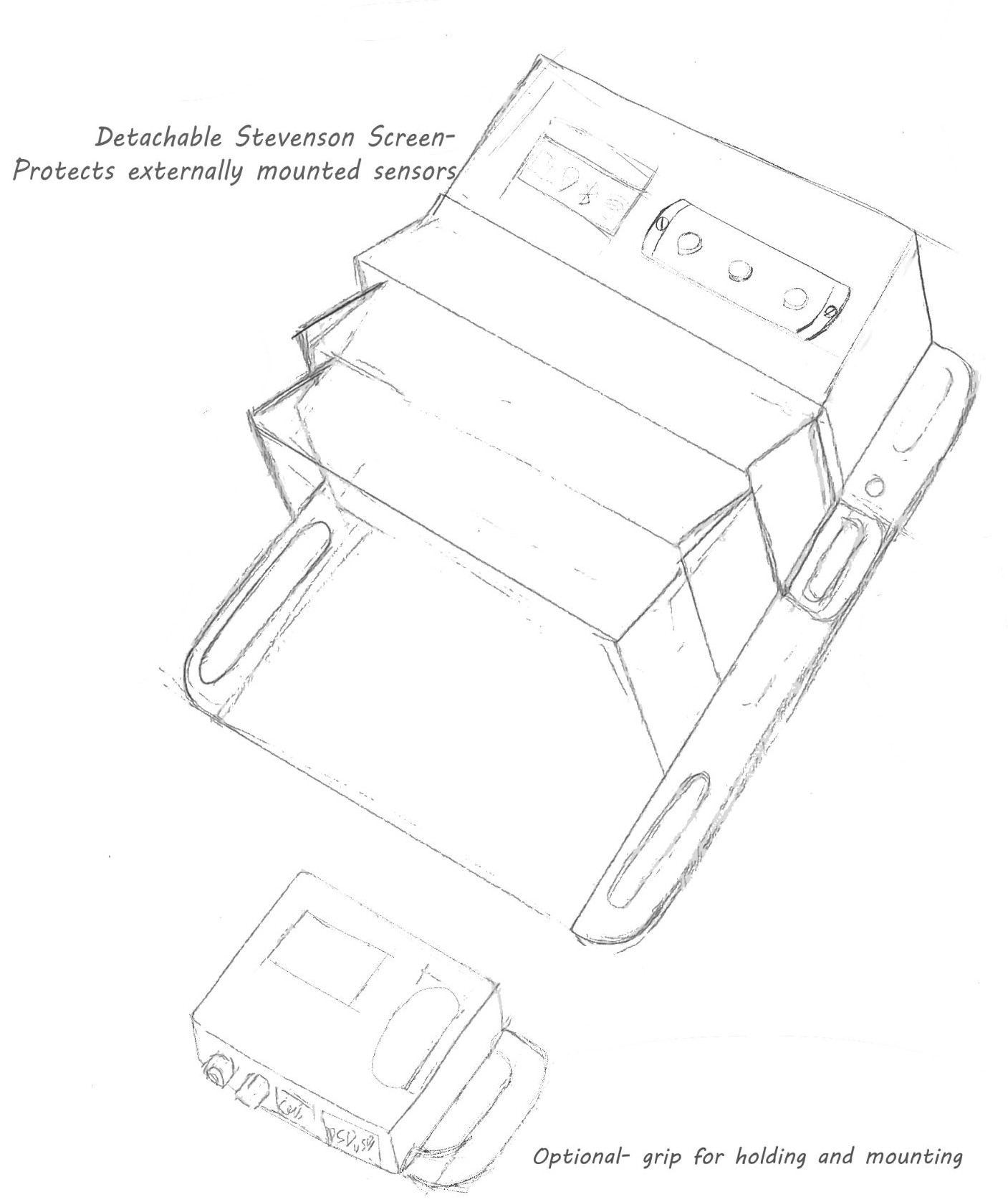

Form Explorations – Base Station

The initial groundwork was established with hardware proof of concepts in the field at Los Amigos in Peru, and based on feedback from the researchers, I explored forms for our base station units.

The designs were heavily driven by the constraints based on our core technology and the stringent requirements of the researchers. It was decided early in the process to combine the base station and handheld receivers into a single device that could serve both roles.

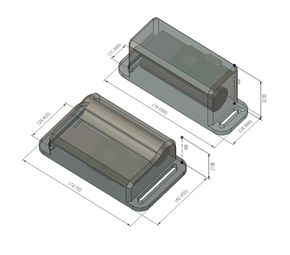

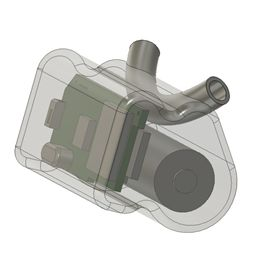

CAD Modelling – Base Station

Prototypes and Testing – Base Station

To enable local fabrication on demand by researchers using our open-source designs, we used commonly available fabrication methods such as FDM printing & laser cutting.

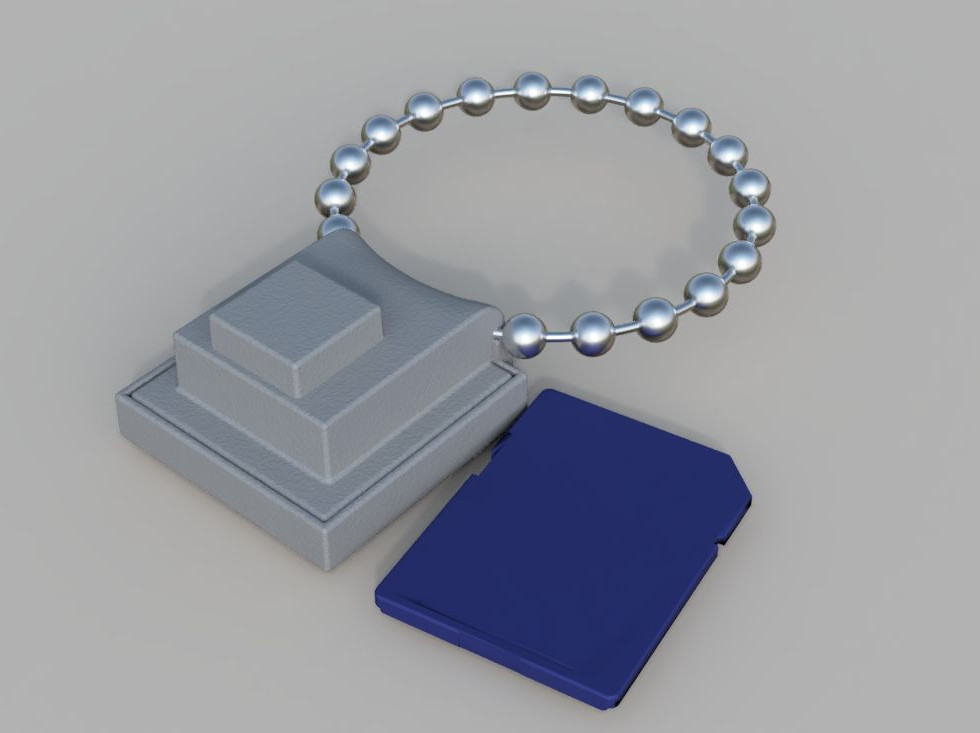

Form Explorations – Collars

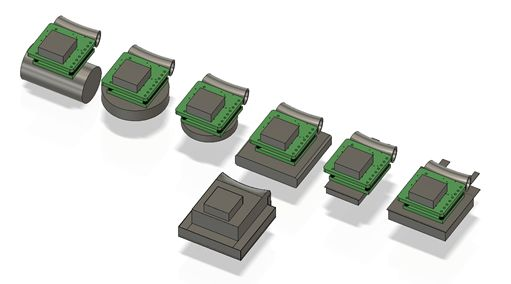

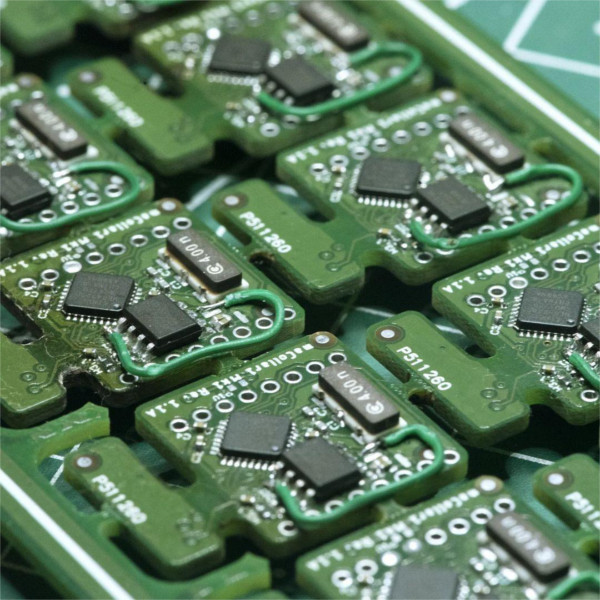

The adult tamarin weighs on average 500g. Any tracker we use must be under 20g in order to avoid interfering with their natural behaviour. After finalizing our technical requirements, we honed our form to optimize weight and runtime.

In addition to designing the electronics, I prototyped the Cases by forming them on a dental vacuum former. The forming bucks were machined from POM on a DIY router.

Through this I was able to keep the collar under 15 grams.

For our larger collars, we had more lenient requirements, and were able to include an electronic break-away mechanism.

Deployment

Our devices were very well received at the fieldsite, and we are actively iterating to improve performance, and further augment the ways in which conservationists can gather data.

Due to ethics concerns, we cannot show images of wildlife, so please enjoy a picture of our local volunteer testing an early prototype.